WIRE ROPES

Classification & Definition of WIRE ROPES

Wire Rope is an intricate device, a composite structure, made of a number of individual units, called wires which are designed and produced in such a manner that they always exit and work in some precise relationship with one another. This precise relationship of individual wires which possess certain defined physical and mechanical characteristics, ensures that the composite wire rope has strength, flexibility and durability essential for safe hoisting applications. Although other elements and factors are significant to successful operation of a wire rope, intended to be used in Elevators, the users of these wire ropes must have a clear understanding of fundamental characteristics of a wire rope to enable them to specify and procure correct wire rope for a particular application.

Wire Rope is an intricate device, a composite structure, made of a number of individual units, called wires which are designed and produced in such a manner that they always exit and work in some precise relationship with one another. This precise relationship of individual wires which possess certain defined physical and mechanical characteristics, ensures that the composite wire rope has strength, flexibility and durability essential for safe hoisting applications. Although other elements and factors are significant to successful operation of a wire rope, intended to be used in Elevators, the users of these wire ropes must have a clear understanding of fundamental characteristics of a wire rope to enable them to specify and procure correct wire rope for a particular application.

Wire Rope Construction

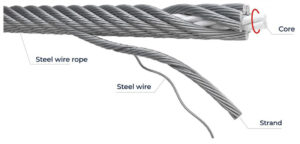

A wire rope has 3 main elements

a) Wire

b) Strand

c) Core

Wire

The basic component of a wire rope is the wire, which is made from steel in various sizes. The number of wires in a strand varies depending upon the usage of the wire rope.

A defined number of wires are spun helically around a central wire to form a strand. A number of such stands are then helically spun together over a core to form a wire rope. The way the wires are spun to form the strands and the way these strands are spun around the core greatly contribute to the overall performance characteristics of the wire rope.

Surface Finish

An elevator wire rope may have wires in either bright finish, which refers to a wire which has no additional metallic coating to resist corrosion, or in galvanized finish, which means that the wire has a coating of zinc.

Elevator wire ropes are generally procured in bright finish and seldom as galvanized but the latter may be produced on demand.

Tensile Grade

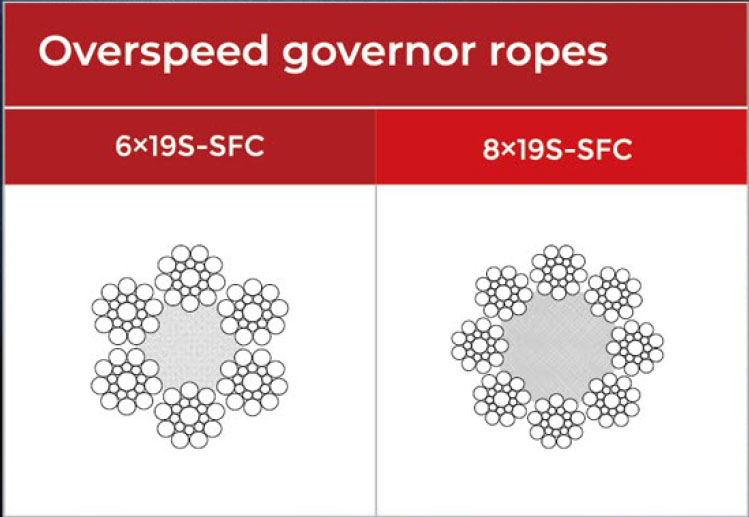

The tensile grade of a wire rope referes to the tensile of its constituent wires. For eg. in 1/2″ 8 x 19S Dual or 9.5mm 8 x 19W 1570 the expressions Dual and 1570 refer to the tensile strength of its constituent wires. A dual tensile grade normally implies that outer wires are of lower tensile and inner wires are of higher tensile, for eg. 1180/1770 or 1370/1770

Note : Standards such as ISO 4344 and EN 12385-5 refer these tensile designations in place of Iron, Traction and EHS grade which are commonly used in the United States. 1180/1770 or 1370/1770 grade may be used in place of Traction ropes and 1570/1770 grade in place of EHS ropes. The iron grade has no equivalent in these international standards as its lower tensile strength has generally made it obsolete in most hoisting applications. While some older equipment may still specify Iron Grade for Governor Rope applications. most newer equipment is using 1180/1770 grade material.

Strand

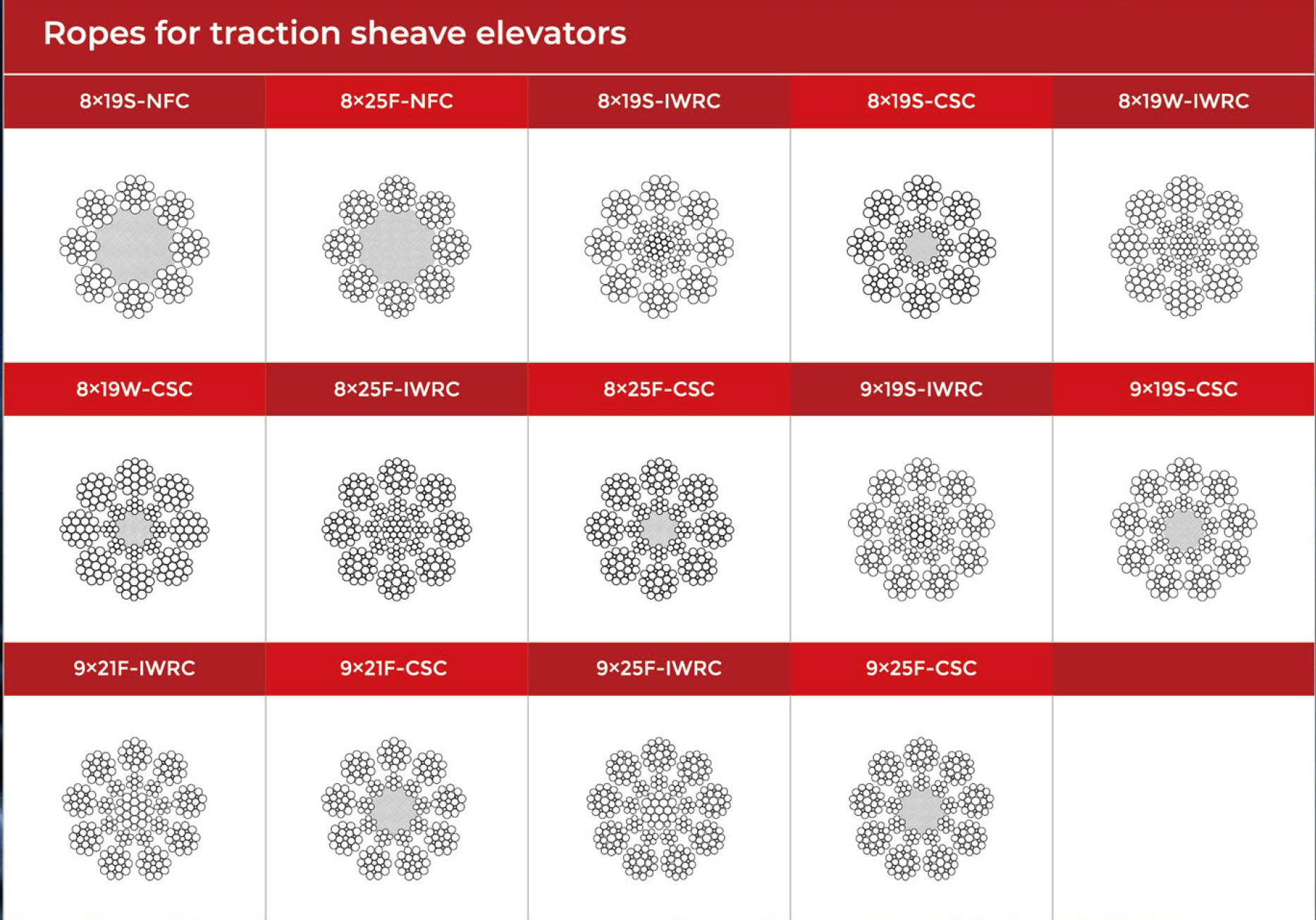

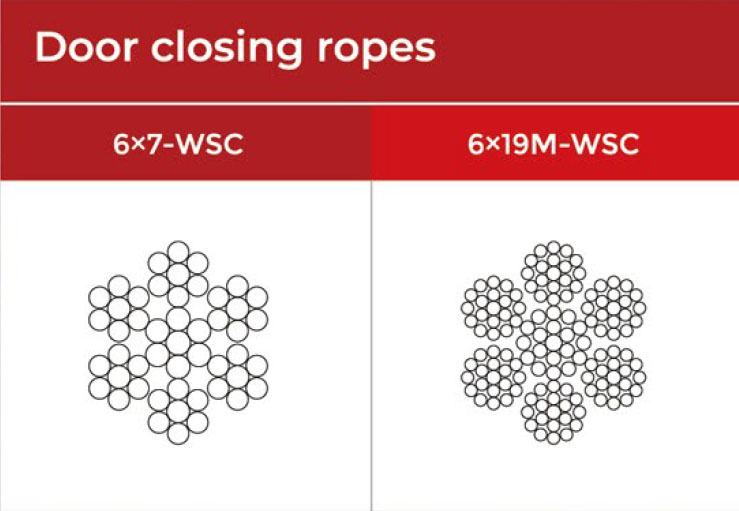

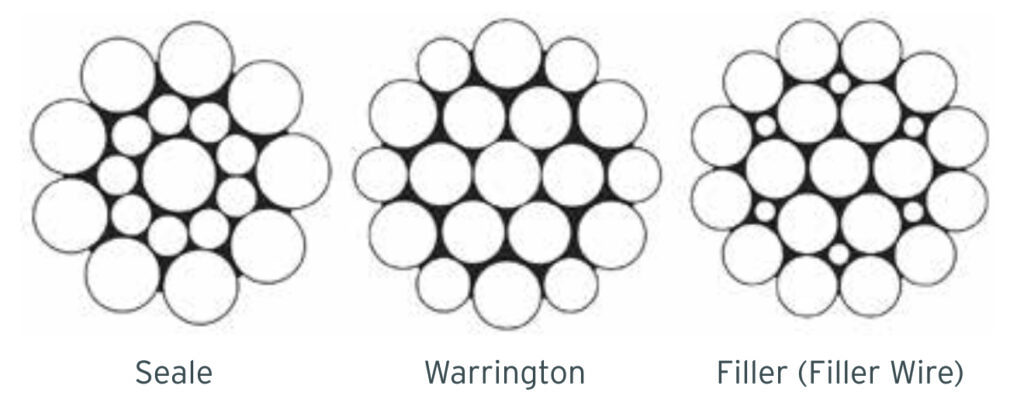

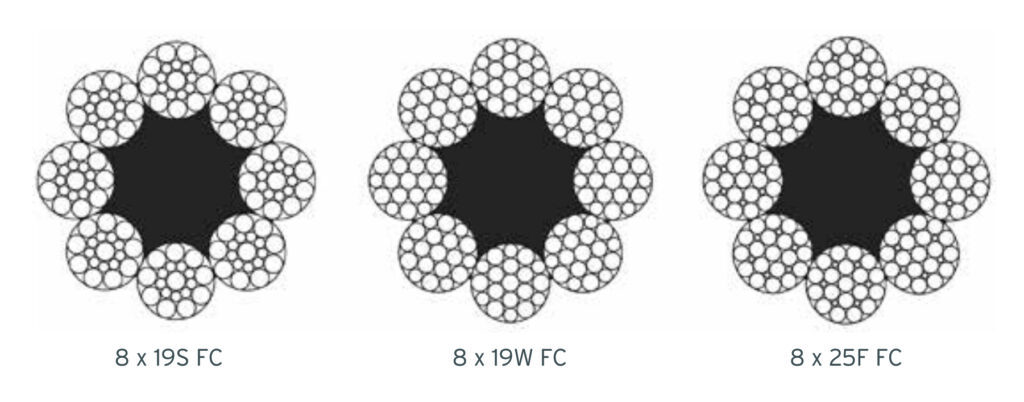

The geometrical arrangement of wires in the strand is called its construction. The most common strand construction are Seale, Warrington and Filler (Filler Wire)

Seale

Seale has larger diameter of wires on the outer layer to resist abrasion and has an equal number of smaller wires on the inner layer to provide flexibility.

Warrington

Warrington has an alternative arrangement of smaller and larger wires on the outer layer to combine flexibility with abrasive properties.

Filler (Filler Wire)

Filler Wire has smaller wires filling the empty spaces between the outer and inner wire layer and offers better fatigue properties along with good abrasion resistance.

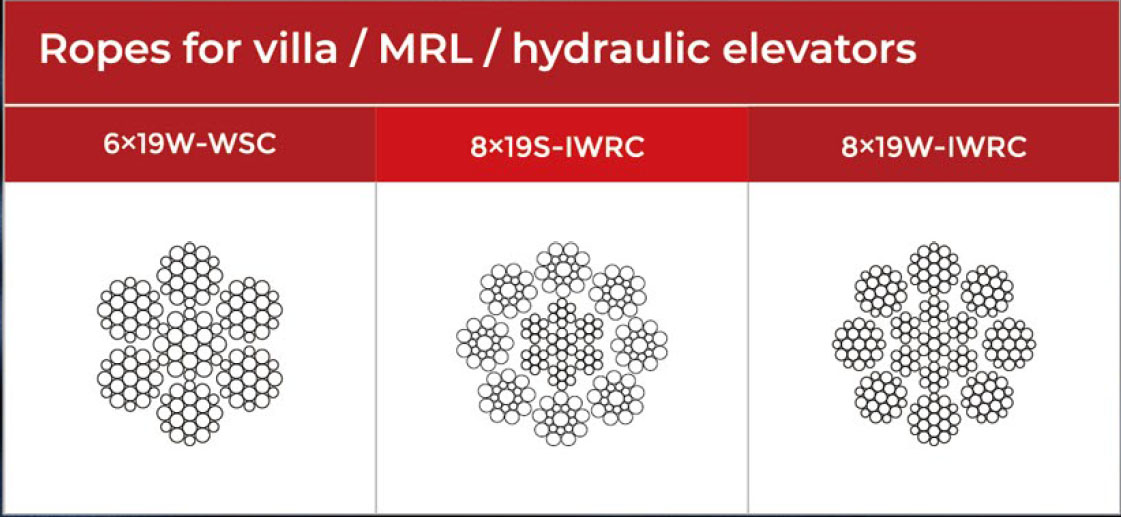

Core

It is the core, which provides support to the outer strands and offer integrity to the wire rope. A wire rope can have a steel core (wire strand core-WSC or independent wire rope core – IWRC) or a fibre core (Natural-Sisal or Synthetic-Polypropylene). For Elevator ropes IWRC is almost always prefered as steel core.

The fibre core provides increased flexibility to the wire rope and in some cases act as a reservoir of lubricant. An independent wire rope core is wire rope in itself, which is used to strengthen the rope and provide resistance to crushing. Its flexibility is however less than a wire rope with fibre core.

Wire Rope Construction

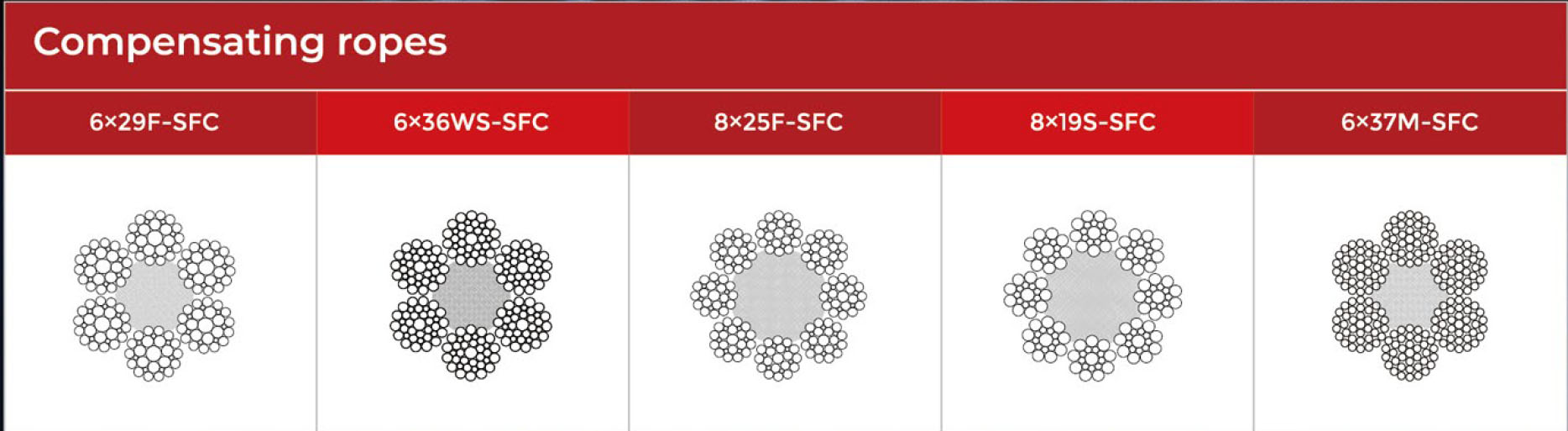

A wire rope is designated by the number of strands and the construction of its strand. For eg. 8x19S denotes that it is composed of 8 strands and each strand has 19 wires spun together to form a (S) Seale construction. Some other common strand constructions for elevator products are Warrington and Filler and are available in 6, 8 and 9 strand rope construction.

OVERVIEW OF ELEVATOR WIRE ROPES